SBB's factory has the necessary equipment to perform FSW and final machining in one machine. We praise ourselves for the quality of our processes, team and equipment; this is why every time we collaborate with our clients, our FSW, manufacturing and industrial design experts not only assess the feasibility of our client's projects but also work closely to ensure their final product meets the highest quality standards and their manufacturing process benefit from the advantages of this new mode of production.

Principle

To summarize the principle of operation, this welding practice makes a junction between two components in the solid state by jointly applying intense pressure and friction at the point of contact between two adjacent surfaces.

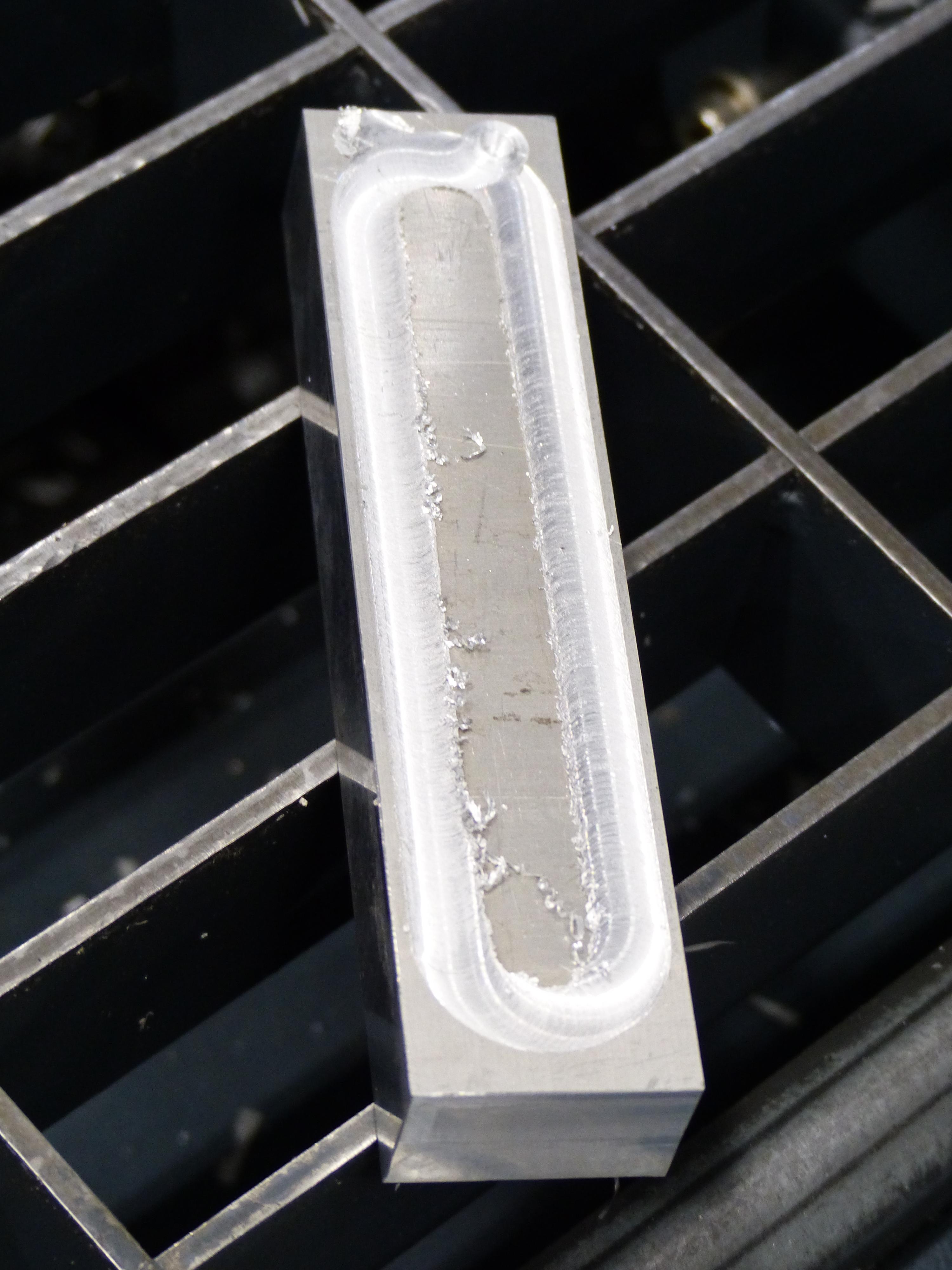

The rotary movement of the specific tool used creates heating which "plasticizes" the material in the welding axis to finally mix the interfaces. The heat is, however, exceptionally controlled and relatively well-defined in the weld area. Indeed, during welding, the melting temperature of the welded metal is not reached but remains 60-80% compared to the melting point.

Friction Stir Welding / FSW : The advantages

FSW has several advantages for the aluminium industry.

Firstly, it produces high-quality welds without porosity, solidification defects, or cracking.

Secondly, FSW produces welds with excellent mechanical properties, such as high strength and fatigue resistance. This makes it particularly useful for joining thin aluminium sheets, commonly used in the aerospace and automotive industries.

Thirdly, FSW is a relatively simple and easy-to-automate process, which makes it particularly useful for high-volume production. This makes it ideal for the aluminium industry, which requires high-quality and high-volume production for many applications.

SBB choose to invest in this innovative aluminium welding system and this new equipment because not only this represents an excellent potential for automation and productivity gains, but it also holds many advantages for its customers:

- Improved reliability and repeatability once welding parameters have been defined

- Fast process in one pass

- High resistance and sealing of the weld, absence of porosities, inclusions, cavities or blisters

- Aesthetic outcome due to the regularity of movement and the flatness of the weld, which does not require machining or cleaning. Finally, the finishing of the back of the joint is entirely acceptable, and its reprocessing is optional.

- Ultimately, the mechanical properties of the assemblies are improved: traction, fatigue, tension, and bending.

- The visual inspection phase is also accelerated thanks to the high quality and clean finish.

Increased safety for employees and a greener process

The method provides employees with a safer work environment, free from radiation, molten spatter, dust and toxic fumes that usually accompany arc or fusion welding (including GMAW, GTAW, and SMAW). In addition, no chemicals are needed to accompany welding. We can accordingly describe the production as "clean". Shielding gas is also no longer necessary, eliminating all the problems associated with its use and storage.

Technicians simply need safety glasses to approach and monitor their machines. Even the limited heat does not cause discomfort, and an aluminium part can be grasped with the hands soon after manufacturing.

New and multiple possibilities, especially in the transport sector

This process efficiently welds high-strength extrusion aluminium, such as 2000, 6000 and 7000 series aluminium alloys. These are difficult to weld by conventional fusion because of their sensitivity to solidification cracking and the degradation of their mechanical properties due to heat.

FSW is also suitable for sheet metal (3000, 5000) and casting (A356) aluminium.

SBB can thus meet a broad set of high-quality welding needs for various uses:

- Welding of extrusions

- Welding of molded parts

- Welding of parts made of materials non weldable by fusion, up to 12mm thick

Since the final products gain in lightness compared to conventional welding (especially alloys 2000, 6000 and 7000), some sectors where weight is a challenge pay particular attention to all these manufacturing qualities, including the transport sector: rail, automobile, shipbuilding, aeronautics or aerospace… but also energy or defence.

Indeed, FSW Friction Stir Welding is an excellent alternative to riveting and bolting. Typically, in aeronautics, the high-strength aluminium alloys used for the fuselage are not weldable by conventional welding.

That's why thousands, even millions, of rivets are used on planes. However, FSW can efficiently weld these alloys and eliminate a large part of the rivets (up to 60%), which results in significant weight savings.

Using rivets also reduces the integrity of the parts: the holes create places prone to degradation and corrosion. FSW eliminates this problem and thus increases the life of the parts concerned, which can be valuable on a bridge or shipbuilding.

Let's take, for example, SpaceX. They quickly understood all the value of this technology and are already using it for manufacturing aluminium tanks for its Falcon 9 rocket. These elements are suffering from considerable pressure, so thanks to stronger FSW welds, it not only allows for thinning the walls but also ensures their perfect seal while reducing the overall weight of the rocket. Tesla and Honda are using FSW for the battery boxes of their electric cars. BRP, Bombardier's Recreational Products Division, applies FSW to Skidoo radiators.

To sum up, the top 10 advantages of FSW, friction stir welding, are:

- A high welding speed

- No filler material

- Superior mechanical properties: weld with improved strength, resistance, sealing and durability

- Less distortions, and therefore better controlled final dimensions

- Final weight assembly reduced

- An aesthetic weld

- An increased lifespan of the products concerned

- A process suitable for aluminium alloys, sheet metal and foundry aluminium and for dissimilar materials

- Greener production

- A safer workplace

SBB: A pioneer in using Friction Stir Welding Technology in Quebec

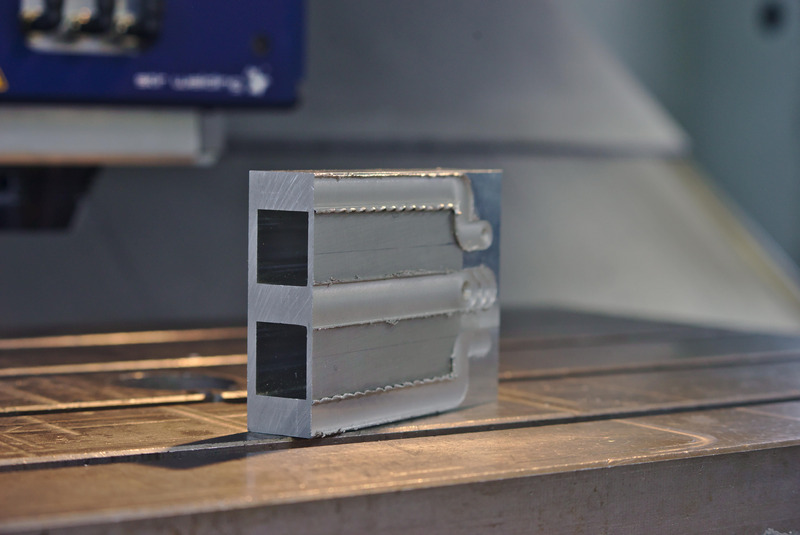

In 2015, the company partnered with the Quebec University in Chicoutimi (UQAC) to start a concrete production of large, complex parts with several stages of manufacture. Intended to compose the roofs of light rail wagons made by Alstom, these large structures have forged SBB's FSW experience.

Consult our Customer Cases to find out more

This order galvanized the avant-garde spirit of our engineering and machining teams, who were deeply involved in mastering this latest generation of welding. Furthermore, our path towards a more innovative welding process was enriched by the active participation in forums organized by the leading market players who supported SBB's interest and commitment to this innovation: AluQuébec, CQRDA (Quebec Center for Aluminium Research and Development), Alcoa Innovation, CMQ (Quebec Metallurgy Center) and RTMQ (Quebec Metal Transformation Network).

Since 2019, this tool has been installed in one of our CNC machining centers in our Blainville factory.

Many steps have forged our experience, and we are happy to have successfully completed them to internalize these tools and skills, opening up new manufacturing perspectives.

Our Production and Engineering departments are available to discuss all your projects requiring innovative welding and high-performance results, both in prototyping and manufacturing.