fabrication and

machining

SBB deploys its activity within a 30 000 sqft factory with 28 feet high ceiling:

- Team of expert welders in TIG and MIG

- 2 Fanuc robotic welding arms which can weld up to a radius of 3 meters, and in all directions thanks to their 6 axes of movement

- Friction Stir Welding (FSW)

- Overhead cranes with lifting capacities of up to 25 tons

- Production of parts up to 12 meters long

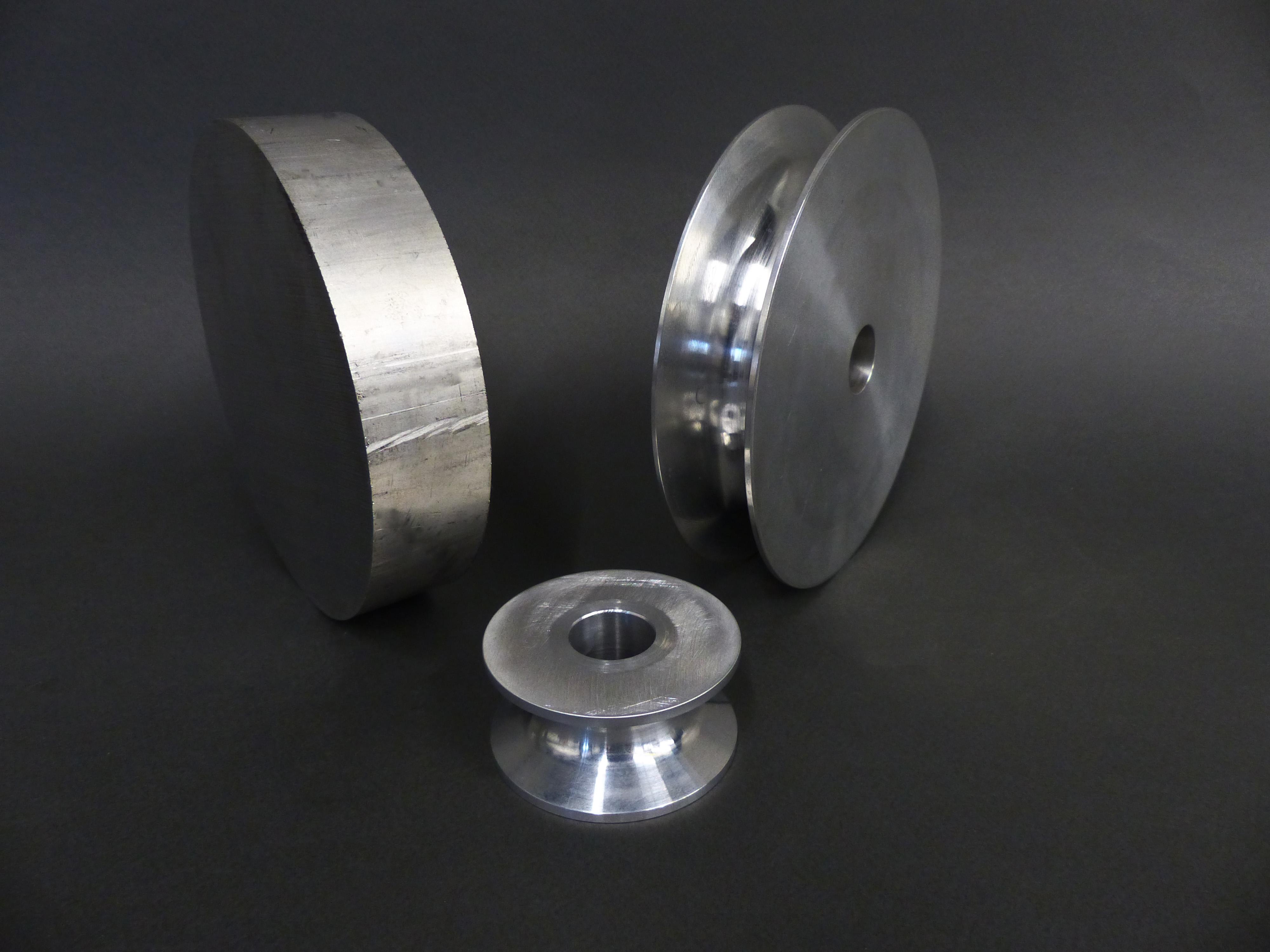

SBB has also a machining departement, with perfect control of the entire production process, thanks to the following equipment:

** 4x 3-axis vertical milling machines

- Manford D4112 (157"x 36“x 48") with a removable 4th axis

- VMC 1000 (39"x 25"x 21")

- VMC 830 (32"x 16"x 48”l)

- Akira Seiki Dorado (16"x 14"x 12") on which 2 pieces can be worked simultaneously

** 1 lathe for turned parts up to 18" in diameter

- John Ford SL-50 (22"x 18" Ø)

** 1 band saw for cutting with great precision

- IcoCut (14"x 13")

We adapt our templates, our teams and our working methods to meet your special projects requirements.